Mixing sea and freshwater has become a business opportunity

-

Loes Elshof

Loes Elshof

Share article:

Salinity Gradient Energy creates economic opportunities for areas where rivers flow into the sea. Technologies for generating electrical energy from ‘just’ mixing sea and river water is the ultimate blue answer to sustainable energy. In Italy (Milano), Spain (Granada) and several places in the Netherlands progress is being made on developing new types of technologies.

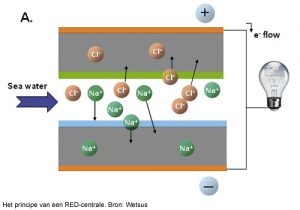

The principle of Salinity Gradient Energy is that electricity can be generated from salinity differences in two types of water. When two solutions are brought together, dissolved species like ions will tend to distribute evenly over both solutions. In this case one of the solutions contains sodium chloride (seawater) and the other type is less or non-saline (river water). The tendency for mixing is the driving force that can be used to extract electricity.

Salinity Gradient Energy

The concept of Salinity Gradient Energy was formulated in 1954 by R. Pattle in Nature (174). At that time it was clear that much more research was required in order to create economically viable technologies. In the seventies the first technology, Pressure Retarded Osmosis (PRO), was developed in Israel. In 2009, the world’s first osmotic power plant with capacity of 4 kW was opened by Statkraft in Tofte in Norway. Even though the process was working, it turned out not to be cost effective. Although a commercial plant had been planned, in 2013 Statkraft announced that the osmotic plant was shut down. But the concept of Salinity Gradient Energy is continuously popular; not only in Europe, but in China and the United States as well researchers are working on operating these osmotic technologies.

Reverse Electro Dialysis

A dominant and promising technology is Reverse Electro Dialysis (RED). RED is just implemented in the Netherlands (Afsluitdijk) by REDstack, a spin off enterprise of the Dutch water institute Wetsus in Leeuwarden. Wetsus is project partner in the actual project together with membrane producer Fujifilm. In the prototype power plant a surface of over 400 m2 of membranes has already been installed. Every hour 220.000 litres of salt and non-salt (river) water is passing through the innovative membranes and thus charging energy. Points of attention are scale, maintenance of membranes and the amount of energy needed to pump the water through the tiny spaces between the membranes. The next step is aiming at operating a cost effective power plant that will produce electricity to the grid. A considerable augmentation of the membrane surface is needed as well.

A dominant and promising technology is Reverse Electro Dialysis (RED). RED is just implemented in the Netherlands (Afsluitdijk) by REDstack, a spin off enterprise of the Dutch water institute Wetsus in Leeuwarden. Wetsus is project partner in the actual project together with membrane producer Fujifilm. In the prototype power plant a surface of over 400 m2 of membranes has already been installed. Every hour 220.000 litres of salt and non-salt (river) water is passing through the innovative membranes and thus charging energy. Points of attention are scale, maintenance of membranes and the amount of energy needed to pump the water through the tiny spaces between the membranes. The next step is aiming at operating a cost effective power plant that will produce electricity to the grid. A considerable augmentation of the membrane surface is needed as well.

Capmix

RED is not the latest technology for Salinity Gradient energy. Recently another type has been developed, called Capacitive mixing, both in Italy and the Netherlands (Wetsus, REDstack) at the same time. This technology is based on the use of two electrodes of active carbon with membrane covers that are put into sodium chloride water. One electrode selects the negative ions and the second one the positive ions. This process causes an electron flow that is charged by a ‘capacitator’ in the water. When the salt water is changed into fresh water, the process restarts automatically in reversed order, and thus producing electricity. Olivier Schaetzle: “Capmix is a new process that can possibly overcome issues of more advanced technologies: it is a cyclic process where salt and fresh water are alternatively fed to the system. As a consequence we expect possibly less fouling issues as we make life for microorganisms more difficult. Pollutants getting stuck on the membranes during one phase are being removed during the other. In addition, Capmix offers the possibility of more flexible designs. This allows a better hydraulic distribution and thus a possibly less energy intensive pumping requirement, compared to other technologies.

The advantage of Capmix is that the electricity generation is directly linked to the mixing process. No additional conversions are necessary and there is no need for complex converters like turbines or electrochemical reactions. Another ‘plus’ is that the energy can be generated continuously, not dependent on weather circumstances – like other renewable energy sources such as solar and wind energy.

Improvement

Still, at the moment Capmix is not yet performing at the same level as RED in electricity production. Schaetzle expects Capmix to develop further next years: “The tests in real life conditions gave us a lot of information regarding the direction the research should take in order to improve the technology. This will lead to new designs and procedures. Capmix will change, just like RED has been improved by the results of the Capmix-research.”

Cooperation in research

In 2010 the institutes in Italy and the Netherlands agreed on continuing research together within the Capmix-consortium along with new partners. Besides Wetsus and Universita’ Degli Studi Di Milano-Bicocca, Politechnika Wroclawska and Universidad de Granada (Spain) joined, along with the private companies REDstack and MAST Carbon International. The research project received 2.4 million euro from the European Union, and was finished last September.

The project included common activities and in September the final results were presented: The Spanish university produced models for fundamental understanding of the concept. The Italian developed an alternative for membranes on the electrode-tops: a chemically modified carbon. The Dutch have operated an up-scaled pre-prototype for Capmix. It is 20 times bigger than the lab-scale units has been running successfully in artificial conditions and is now being tested in the RED-facility at the Afsluitdijk. Olivier Schaetzle: “We are taking a lot of effort in finding new funding for Capmix – in the meantime research is continuing at lower speed. Finding new funding is not easy as the technology is very specific – comparing to technologies that produce electricity from waves and tides.”

New concepts of mixing

Speaking of results, the concept of mixing substances has led to developing new stream of concepts. Schaetzle: “We have adapted the concept to other materials and substances, like Carbon dioxide with air. We can extract electricity from mixing these two different types of gases.” This concept could be of use in industrial surroundings, were Carbon dioxide is produced. The mixing technique with Carbon dioxide, considered as “High risk-gain” hopes to receive funding from the EU Research Council. “The story of mixing is not over yet”, Schaetzle concludes.

More information

www.capmix.eu

www.redstack.nl